Gallery

1943

1941. As a Seaplane Tender

Slide title

On active service circa 1945

Button

Slide title

At Pembroke Dock - 1940s?

Button

Slide title

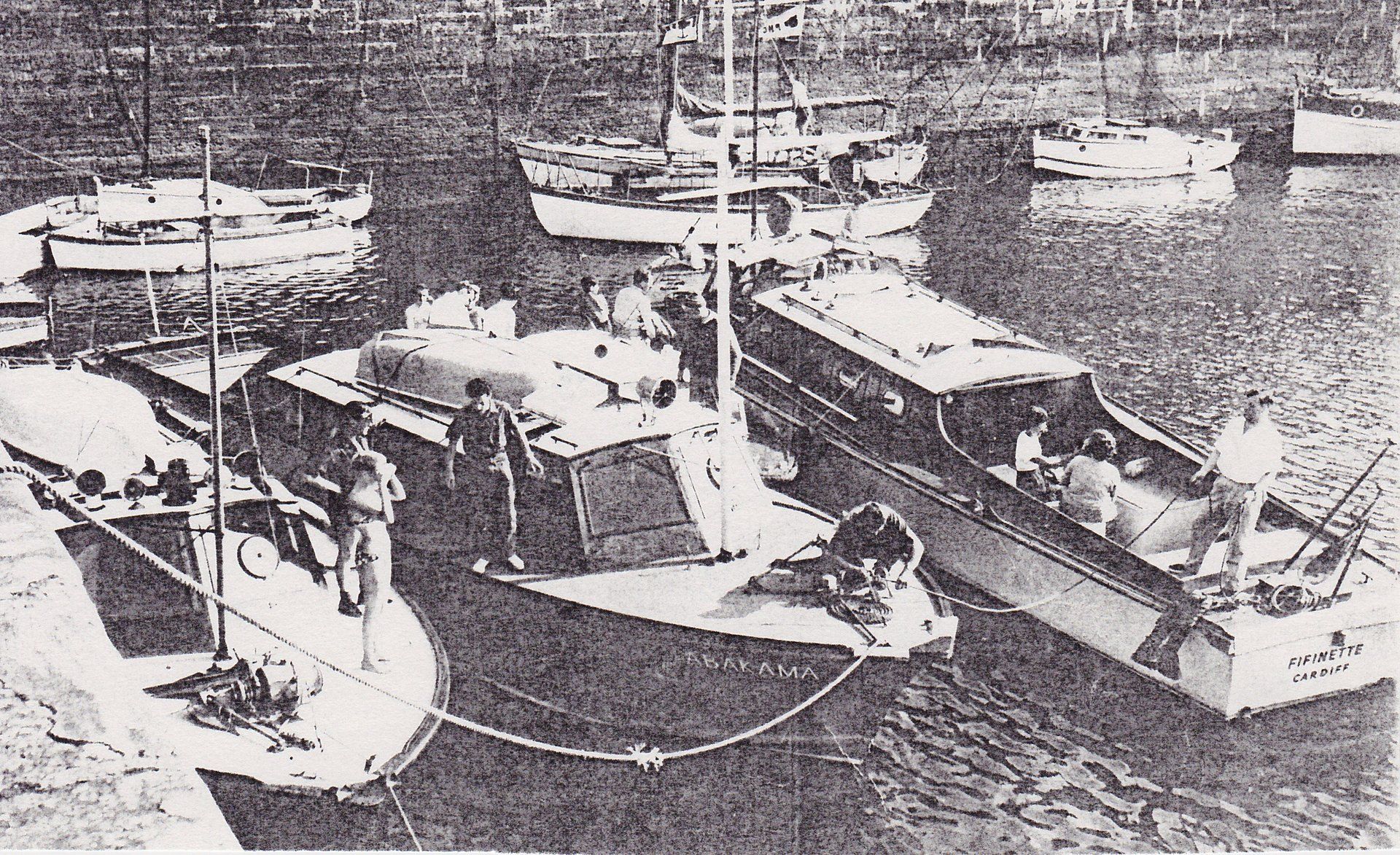

437 (middle) with two other STs in the late 1950s

Button

Slide title

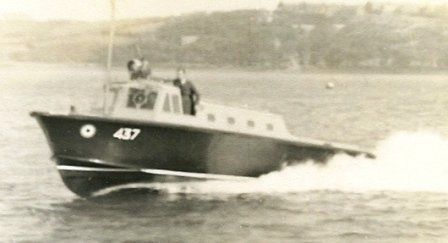

437 at speed in the Bristol Channel circa 1960

Button

Slide title

In the River Ely, Penarth, in the 1970s

Button

Slide title

Abakama (437) in Penarth circa 2000

Button

Slide title

ST437 at sea in 2015

Button

Slide title

On active service circa 1945

ButtonSlide title

2017. Lying at Watchet

Button

Slide title

Happily at rest

ButtonSlide title

Should I trust this man??

ButtonSlide title

Pre-flight checks...

ButtonSlide title

Lift off!

ButtonSlide title

Up, up and away

ButtonSlide title

ButtonSlide title

Flying boat service!

ButtonSlide title

Lovely bottom!

ButtonSlide title

On final approach...

ButtonSlide title

...and a smooth touchdown

Button

Proper preparation, etc.

First raise the vessel off her stands - car jack at one end, tractor at the other - obviously...

ButtonSlide title

Then position tailor-(welder) made trolley

ButtonSlide title

Pause to consider...

ButtonSlide title

Next, rotate the boat through 180' in a space that is too small.

ButtonSlide title

Manoeuvre the boat using the tractor... carefully...

ButtonSlide title

It's not going to fit!

I did the maths. My O'level grade U is coming to the fore.

ButtonSlide title

Told you. With millimetres to spare. Easy peasy.

ButtonSlide title

Home and dry.

ButtonSlide title

We few, we happy few! Plus the photographer/tractor driver.

Thank you, Gentlemen.

Button

Our resident glass specialist...

Button

Slide title

The wheelhouse roof

ButtonSlide title

Half off - unbelievably stubborn!

ButtonAll gone

ButtonThe (recently replaced) roof timbers.

ButtonLooking forward from the main bulkhead.

Button

How the transom looked on arrival - yes, those are trim tabs!

The repairs to the transom - probably wartime damage.

ButtonAndrew starting the removal...

And even Fraser getting his hands dirty!

ButtonAnd Justin dismantling the frame.

Slide title

Baron checking my work...

ButtonJo doing what Jo does best (?!)

Ready for replacement.

Cutting out the rot.

Almost ready for the

repair piece.

Shaping the corner posts

First tentative dry-assembly.

The first major task was re-planking the topsides.

The boards were secured with hundreds of bronze screws, mostly rotten along with dozens and dozens of copper rivets, which were not.

Removing the planks revealed the extent of the damage to the ribs and seam battens. We replaced all the seam battens and any ribs that were beyond salvation.

Once the starboard side was re-planked, on with the port side.

First remove the plank

Repair the ribs...

Replace the seam battens

Replace with the new boards

Repeat...

And repeat...

And presto!

Over the years, the deck has been replaced several times. It was originally double diagonal mahogany; by the time I got to her, she was covered in a myriad of small pieces of plywood - all rotten.

We were able to salvage two of the foredeck frames, with some inlaying of new timber and had to replace eleven of the side deck frames.

I am going to replace the deck with teak.

The deck was in a bad state

Slide title

A very bad state

ButtonSlide title

From stem to stern

ButtonSlide title

Repair or replace..?

ButtonSlide title

Trying to save what I can

ButtonSlide title

This was a nice find

ButtonSlide title

Deck structure replaced

Button

Starting on the inside was an exciting moment - until we discovered that the internal timbers were as rotten as those on the outside.

She only had one stringer - and that was broken - so there was no question that serious replacement works were needed.

Dirty, oily and broken

Make new ribs as necessary

Peaning the stringers

A matched pair

Stringers in place

Slide title

Then the floor supports

One of the reasons the port-side engine was blown was because the stern-tubes has been re-tightened so many times, they were no longer aligned with the prop shaft. This resulted in too much strain on the engine - and massive, terminal wear to the shafts.

Solution - to let in a section of hardwood to give a new, durable base for the bronxe stern-tubes.

Slide title

A bit of thought and planning

ButtonSlide title

A router jig made up and positioned

ButtonSlide title

The tube-log routed to 16 mm

ButtonSlide title

And the fashion-piece inserted and epoxied/screwed in place

Button

There has been a lot of preparation involved in getting the cockpit bilges sorted and getting the sole frame installed.

The stringers were built 18 months ago and have been taking up space in the workshop. Time to bite the bullet and get the cockpit done.

Slide title

The starting point - nasty, oily mess

ButtonSlide title

One of numerous treatments with Fullers Earth to remove the oil

ButtonSlide title

Finally, a paintable surface

ButtonSlide title

Prep before painting

ButtonSlide title

Primer...

ButtonSlide title

Two undercoats...

ButtonSlide title

Two topcoats...

ButtonSlide title

... and the paint has 'bound' nicely

ButtonSlide title

The stringers waiting to be installed

ButtonSlide title

Et voila!

Button